BLOG

SIPOC Diagrams VS Turtle Diagrams

The SIPOC diagram stands for Supplier Input Process Output Customer. Like the turtle diagram, the SIPOC is a schematic representation of the elements of a single process - starting with the supplier and ending with the customer.

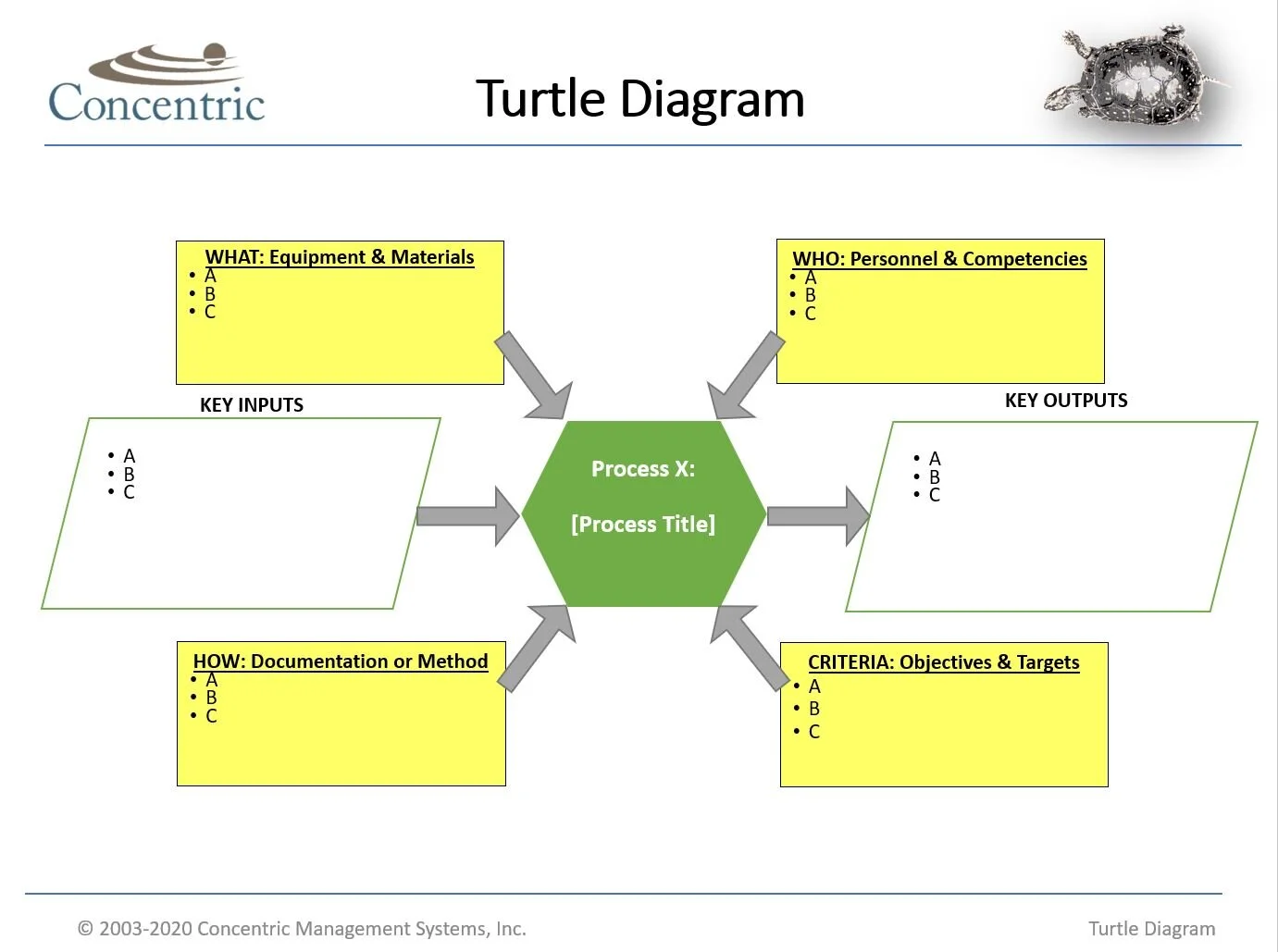

Turtle Diagrams

A "Turtle Diagram" is a quality tool used to visually display process characteristics such as inputs, outputs (expectations), criteria (metrics) and other high-level information to assist in the effective execution and improvement of key business processes.